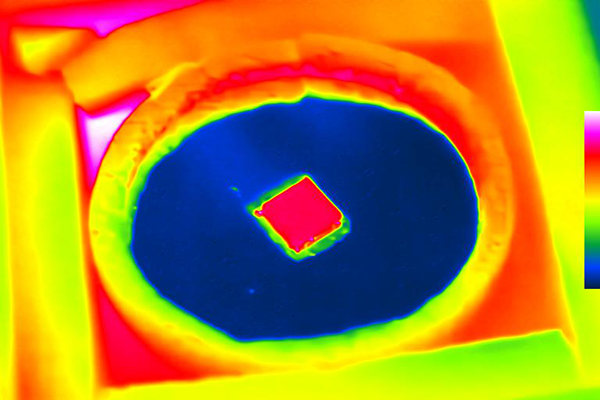

Infrared thermal imaging technology relies on advanced sensor materials to detect and image heat signatures. These materials are typically categorized into Cooled and Uncooled detectors, each offering unique advantages in sensitivity, range, and application suitability. This article provides an in-depth look into the leading sensitive materials for infrared detection, including both photonic and thermal detectors.

Cooled Infrared Detector Materials: MCT, TSL, QWIPs, II-SLs, and QDIPs

Cooled infrared detectors operate at low temperatures to minimize noise, achieving high sensitivity. They use photonic materials such as Mercury Cadmium Telluride (MCT), Type II Superlattice (TSL) structures, Quantum Well Infrared Photodetectors (QWIPs), Quantum Dot Infrared Photodetectors (QDIPs), and II-Superlattice (II-SLs) to detect infrared radiation.

- Mercury Cadmium Telluride (MCT or HgCdTe): MCT is a direct bandgap semiconductor material that covers a wide wavelength range (1–30 µm) by adjusting its atomic composition. Its high absorption efficiency and quantum efficiency (often above 80%) make it highly sensitive to infrared light. However, MCT detectors are challenging to produce, particularly for wavelengths longer than 12 µm, requiring sophisticated manufacturing techniques to achieve low dark currents and noise levels.

- Quantum Well Infrared Photodetectors (QWIPs): QWIPs use a quantum well structures consisting of a small number of layers to efficiently detect infrared radiation. While QWIPs provide stable performance and are commercially viable for certain long-wave applications, they have limited quantum efficiency and respond only to light parallel to the growth plane.

- Type II Superlattices (II-SLs): InAs/GaSb-based II-SLs offer tunable bandgaps, covering a broad range from mid-wave to very long-wave infrared (3–30 µm). Leveraging III-V semiconductor technology, II-SLs are known for high material uniformity and device consistency, making them a promising option for focal plane array production, especially for long-wave applications.

- Quantum Dot Infrared Photodetectors (QDIPs): QDIPs, composed of nanostructured quantum dots, offer multi-spectral detection capabilities and are well-suited for specific niche applications in infrared imaging.

Uncooled Infrared Detector Materials: Vanadium Oxide (VOx) and Amorphous Silicon (α-Si)

Uncooled infrared detectors operate at room temperature, making them more cost-effective and accessible than cooled alternatives. The primary materials for uncooled infrared sensors are Vanadium Oxide (VOx) and Amorphous Silicon (α-Si).

- Vanadium Oxide (VOx): VOx detectors are widely used for their excellent Noise Equivalent Temperature Difference (NETD) performance, contributing to superior sensitivity and accuracy. Although manufacturing VOx detectors can be more complex, they deliver high performance in detecting minute temperature variations, making them ideal for high-precision thermal imaging.

- Amorphous Silicon (α-Si): α-Si is easier to produce in large volumes compared to VOx, which helps reduce costs. However, VOx outperforms α-Si in terms of NETD and sensitivity, making it preferable in high-end applications where accuracy is crucial.

History and Evolution of Infrared Detectors

The development of infrared detectors has been marked by several scientific breakthroughs since the early 19th century:

- 1829: L. Nobili developed the thermoelectric infrared detector using bismuth (Bi) and antimony (Sb) thermocouples, a milestone that led to the invention of the thermopile.

- 1880: Samuel P. Langley invented the bolometer, which measures radiation through temperature-dependent resistance changes in metals, laying the foundation for modern microbolometers used in uncooled infrared detectors.

- 1940s–1960s: Innovations in semiconductor materials led to the creation of new infrared detectors, including Indium Antimonide (InSb) and Lead Sulfide (PbS). By the 1960s, Vanadium Oxide (VOx) emerged, with high resistance-temperature coefficients, establishing its role in uncooled infrared applications.