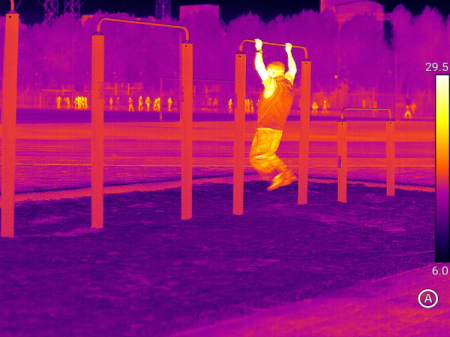

Thermal imaging is a powerful technology that detects infrared radiation emitted by objects and converts it into visible images. It has revolutionized industries like firefighting, security, and industrial maintenance by providing visibility in complete darkness, smoke, and challenging conditions. However, a common question arises: Can thermal imaging see through glass?

The short answer is no—thermal imaging cannot see through glass in the way our eyes or visible-light cameras can. Let’s explore the science behind this limitation and the scenarios where thermal imaging excels.

Why Can’t Thermal Imaging See Through Glass?

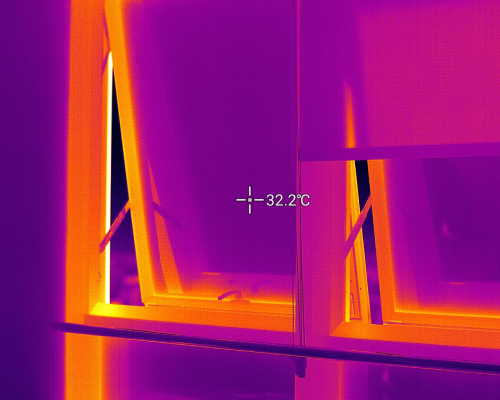

Thermal imaging works by detecting heat (infrared radiation) emitted by objects. Glass, however, has unique thermal properties that interfere with this process:

1. Glass Reflects Infrared Radiation

Glass acts as a mirror for infrared wavelengths. Instead of allowing infrared radiation to pass through, it reflects the thermal radiation back toward the source or the surroundings. This reflection prevents thermal cameras from detecting objects behind the glass.

2. Glass Absorbs Infrared Radiation

Glass also absorbs some infrared radiation, which can distort or completely block the thermal signatures of objects on the other side.

3. Thermal Cameras Detect the Glass Itself

When pointed at a window or glass surface, a thermal camera primarily captures the temperature of the glass itself rather than what lies beyond it. This results in inaccurate readings of objects behind the glass.

Exceptions: Specialized Glass and Thermal Imaging

While standard glass blocks infrared radiation, certain materials and technologies allow thermal imaging to partially or fully detect heat through specialized glass.

1. Germanium Lenses

Germanium is a material that transmits infrared radiation effectively. It is commonly used in thermal camera lenses and can enable thermal imaging through specially designed infrared windows.

2. Thin or Low-Emissivity Glass

Some ultra-thin glass materials may allow limited infrared detection. However, the clarity and accuracy of thermal imaging in these cases are far from ideal.

Practical Applications: Thermal Imaging in Real-World Scenarios

Despite its inability to see through standard glass, thermal imaging remains a crucial tool in many applications:

1. Firefighting

Thermal imaging is invaluable for locating fire sources, even in smoke-filled or dark environments. However, it is less effective when flames or heat sources are behind a window.

2. Industrial Maintenance

Thermal imaging can detect equipment hotspots, electrical faults, and insulation issues. In cases where objects are behind glass, technicians may use infrared windows designed for thermal inspections.

3. Surveillance and Security

Thermal cameras are widely used for monitoring perimeters and detecting intrusions in low-visibility conditions. However, security professionals must account for the limitations of glass in their surveillance setups.

How to Work Around Glass Limitations in Thermal Imaging

If you need to use thermal imaging in scenarios involving glass, consider the following approaches:

- Direct Line of Sight

Position the thermal camera to avoid glass barriers. Direct exposure to the target will ensure accurate temperature readings.

- Use Infrared Windows

Specialized windows made of germanium or other IR-transparent materials allow thermal cameras to capture heat signatures through protective barriers.

- Complement with Visible-Light Cameras

In cases where thermal imaging cannot provide a clear view, pairing it with traditional cameras can enhance overall visibility.

While thermal imaging offers unparalleled visibility in challenging conditions, it cannot see through standard glass due to the reflective and absorptive properties of the material. However, with the right tools and techniques—such as infrared windows or alternative viewing strategies—thermal imaging remains an essential technology in many fields.

Understanding the limitations and strengths of thermal imaging ensures optimal use in applications ranging from firefighting to industrial inspections, keeping people and equipment safe in every scenario.