Refrigerant leaks are a common issue in HVAC systems, leading to reduced efficiency, higher energy consumption, and potential system failures. Detecting these leaks promptly is crucial for maintaining optimal performance and preventing costly repairs. One of the most effective and innovative methods for refrigerant leak detection is using a thermal imaging camera. In this article, we will explore how thermal imaging cameras work, why they are an excellent tool for refrigerant leak detection, and how you can use them for efficient HVAC maintenance.

What is Thermal Imaging?

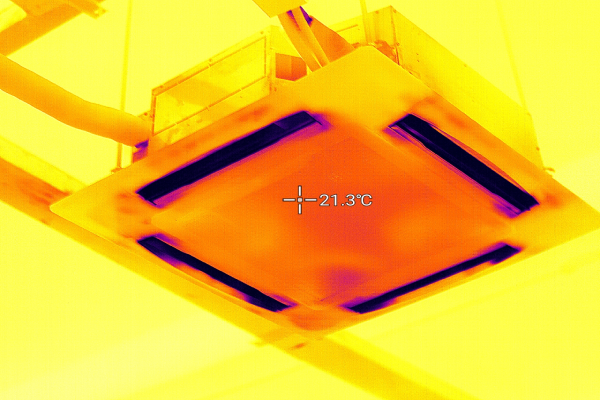

Thermal imaging cameras, also known as infrared cameras, detect infrared radiation (heat) emitted by objects and convert it into visible images called thermograms. These thermograms display temperature differences across a surface, allowing technicians to identify hot or cold spots that might indicate issues such as leaks, blockages, or electrical faults.

How Do Thermal Imaging Cameras Detect Refrigerant Leaks?

Refrigerants, such as R-22 or R-410A, are typically colorless and odorless gases, making them difficult to detect with the naked eye. However, refrigerants are often stored at low temperatures in HVAC systems, and they may cause a noticeable temperature difference when they leak. Here’s how thermal imaging can help:

Cold Spots Indication: When a refrigerant leak occurs, the escaping gas can cause a rapid drop in temperature at the leak site. Thermal imaging cameras can detect these temperature changes, revealing cold spots in the system. By identifying these cold spots, technicians can pinpoint the exact location of the leak.

Frost and Ice Formation: In some cases, escaping refrigerant may cause condensation and even frost formation on surrounding components, particularly in areas where the refrigerant pressure is low. Thermal cameras can detect the cold areas where frost or ice forms, further aiding leak detection.

Non-Contact and Safe: Traditional refrigerant leak detection methods often involve chemical dyes or soap solutions that require direct contact with the system, which can be time-consuming and sometimes unsafe. Thermal imaging cameras offer a non-invasive, contactless solution, ensuring quick and safe leak detection without the need to disassemble the system.

Why Use Thermal Imaging for Refrigerant Leak Detection?

Speed and Efficiency: Traditional methods of refrigerant leak detection, such as bubble solutions or ultrasonic detectors, can be time-consuming and less effective in complex environments. Thermal imaging cameras provide real-time results, allowing technicians to quickly scan large areas and identify leaks without unnecessary delays.

Accuracy: Thermal cameras are highly sensitive to temperature differences, making them incredibly accurate in locating refrigerant leaks, even in hard-to-reach areas. This precision reduces the chances of missing small leaks that might otherwise go unnoticed with manual inspection methods.

Cost Savings: Early leak detection can prevent system malfunctions, avoid energy waste, and extend the lifespan of HVAC equipment. By detecting refrigerant leaks quickly, technicians can make repairs before the problem worsens, saving on expensive repairs or replacements down the line.

Environmental Impact: Refrigerants can be harmful to the environment if released into the atmosphere. Timely detection and repair of leaks help prevent the release of these gases, which is essential for compliance with environmental regulations and reducing your carbon footprint.

How to Use a Thermal Imaging Camera for Refrigerant Leak Detection

Scan the HVAC System: Start by scanning the area around the HVAC unit with the thermal imaging camera. Focus on common leak points such as refrigerant lines, valves, and joints. Pay particular attention to areas where the system experiences high pressure or where components may be subjected to wear and tear.

Look for Temperature Differences: As you scan, look for cold spots or temperature discrepancies on the thermogram. These differences may indicate refrigerant leakage. The colder the area, the more likely it is that a leak has occurred.

Focus on Frost or Condensation: If you notice any frost, ice, or condensation forming around certain components, these could be signs of refrigerant leakage. This is especially common in areas where the refrigerant pressure is low, such as evaporators or expansion valves.

Verify Findings: Once a potential leak is detected, it’s important to verify the findings through further inspection. This might involve using additional tools like ultrasonic leak detectors or pressure gauges to confirm the presence of a refrigerant leak.

Take Preventive Measures: Once the leak is confirmed, proceed with necessary repairs and ensure that the system is recharged with the correct amount of refrigerant. Regular thermal scans can also be a part of preventive maintenance, helping to catch leaks before they cause significant damage.

Best Practices for Using Thermal Imaging Cameras

Ensure Proper Calibration: Before using a thermal camera, ensure it is properly calibrated to avoid inaccuracies in temperature readings. A well-calibrated camera will give you reliable and consistent results.

Work in Stable Conditions: While thermal cameras can detect temperature changes, external factors such as ambient temperature or sunlight can influence readings. It’s best to conduct thermal scans in controlled environments or during periods of stable temperature conditions.

Regular Maintenance: Incorporating thermal imaging scans into regular HVAC maintenance schedules helps catch leaks early. It also helps in identifying potential problems before they become serious, saving both time and money.

Thermal imaging cameras are a game-changer in the field of refrigerant leak detection. Their ability to identify temperature variations, detect cold spots, and pinpoint refrigerant leaks quickly and accurately makes them an invaluable tool for HVAC technicians. By integrating thermal imaging into regular maintenance practices, you can ensure your HVAC systems are running efficiently, reduce environmental impact, and avoid costly repairs. Whether you’re troubleshooting a minor issue or conducting routine inspections, a thermal imaging camera can significantly improve your ability to detect refrigerant leaks and maintain a fully functional HVAC system.