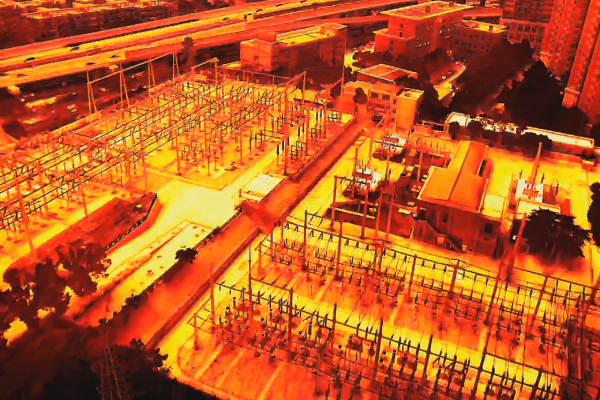

In the modern world of power distribution, substation maintenance is important for ensuring the continuous and safe supply of electricity. One of the most useful tools for monitoring and inspecting substations is infrared thermography, also known as infrared thermal imaging. This method helps detect problems early, saving time and money while improving safety and efficiency.

What is Infrared Thermography?

Infrared thermography uses infrared cameras to capture thermal images of electrical equipment. These cameras detect infrared radiation given off by objects, which relates to their temperature. In electrical systems like substations, the heat from equipment can show problems such as loose connections, overloading, or potential failures. By spotting these heat patterns, maintenance teams can take action before the problems get worse.

Key Benefits of Infrared Thermography in Substation Inspections

1. Early Fault Detection

In electrical substations, even small problems like a loose connection or overloading can cause big damage if not fixed quickly. Infrared thermography helps technicians find temperature differences that may show faults, such as hot spots on switches, transformers, and circuit breakers. Early detection helps prevent power outages and reduce downtime.

2. Non-Contact and Safe Inspection

Infrared thermography allows for remote monitoring of equipment, so technicians do not need to touch high-voltage components. This increases safety by lowering the risk of electric shock or injury, especially when inspecting live equipment.

3. Cost-Effective Monitoring

Regular infrared thermography inspections cost less than waiting for equipment to break down and then doing expensive repairs. Infrared cameras can quickly scan large areas, allowing for regular checks without disrupting operations. This method also helps prioritize maintenance, focusing on areas most likely to fail.

4. Detailed and Accurate Data

Infrared cameras give exact, real-time data on temperature changes. This data can be used to make detailed reports about the condition of each piece of equipment. These reports are helpful for future inspections and for deciding on maintenance schedules.

5. Minimized Downtime

By using infrared thermography for regular checks, substation operators can avoid unplanned outages. Finding potential problems quickly allows for maintenance to be done on time, which reduces the need for emergency repairs that could lead to long downtimes.

Common Applications of Infrared Thermography in Substations

1. Transformer Monitoring

Transformers are key parts of substations, and even small problems can cause big issues. Infrared thermography is used to find unusual heating in transformers, which could signal problems like short circuits or overloads. By watching temperature changes, operators can predict when maintenance is needed, ensuring transformers work safely and efficiently.

2. Circuit Breaker Inspections

Circuit breakers protect electrical circuits from overloads and faults. Over time, connections inside circuit breakers may become loose or corroded, leading to overheating. Infrared thermography helps find these temperature changes and make repairs before a circuit breaker fails.

3. Busbar Inspection

Busbars distribute electricity in substations. If there’s a connection issue, the affected busbar will generate extra heat, which can be seen using infrared thermography. Finding these problems early can prevent failures and extend the life of the busbars.

4. Switchgear and Control Panels

Switchgear and control panels are important for running electrical substations. Infrared thermography can find hot spots inside these systems, which show areas where electrical resistance is increasing, leading to failures. Checking these parts regularly ensures the substation works properly.

5. Power Cable Monitoring

Power cables in substations can have faults like insulation damage or loose connections, which may cause overheating. Infrared thermography helps detect these problems early, reducing the risk of fires and ensuring reliable power supply.

How Infrared Thermography Improves Safety

Substation inspections often involve working with high-voltage equipment, which can be dangerous. Infrared thermography allows technicians to inspect and monitor equipment from a safe distance without touching it. This method not only keeps workers safe but also protects the equipment, as no direct contact is needed.

Infrared cameras can also detect problems in real time, so there is no need for equipment shutdowns or long downtimes. This is especially useful for utilities that need to keep providing power while addressing possible risks. Regular inspections without disrupting service are a big advantage for operators who want to maintain safety.