Infrared thermal imaging technology is gaining increasing importance in the maintenance and inspection industry, as it allows for the rapid and accurate identification of pipeline faults and potential risks.

Currently, multiple types of professional infrared thermal imagers equipped with ROCIR infrared camera cores are being deployed in various pipeline inspection scenarios on a large scale. These advanced tools are enhancing the efficiency and promoting the intelligent upgrading of pipeline-related industries.

In the face of the inefficiencies and complexities traditionally associated with pipeline inspection, new maintenance equipment equipped with infrared thermal imaging technology has emerged as a game-changer. This advanced system offers full FOV, long-range, non-contact temperature measurement, helping to avoid potential damage and promoting energy conservation and emission reduction.

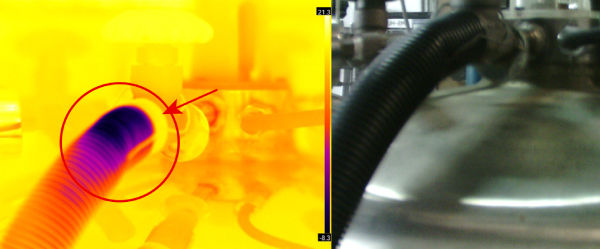

1. Pipeline Leaks: See Through to the Source

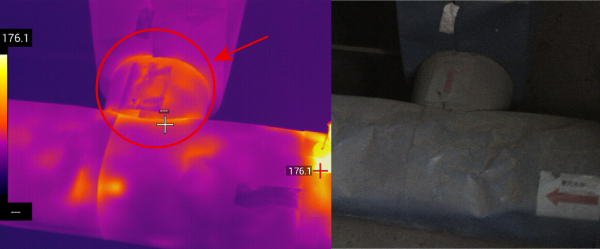

In traditional detection methods, issues such as “leaks and drips” have always been a challenge in pipeline maintenance. When fluids (like gases or liquids) inside a pipeline have significantly different temperatures compared to the surrounding environment, the leakage areas will exhibit noticeable temperature fluctuations. Infrared thermal imaging can directly detect these temperature anomalies, enabling quick identification of the fault’s location.

2. Pipeline Blockages: Abnormal Heat Signals or Blocked Flow

Blockages are a common issue in pipeline systems. Because blocked areas have different thermal capacities compared to other sections, this difference leads to temperature variances that transmit from the inside of the pipeline to its outer surface. By using infrared thermal imaging, any area with abnormal heat distribution becomes immediately visible, which often corresponds to the site of the blockage.

3. Wall Thinning: Uneven Heat, Uneven Thickness

Over time, the inner walls of pipes may become worn down or corroded, leading to thinning in certain sections. Such issues are typically difficult to spot with the naked eye. However, infrared thermal imaging acts as a “third eye,” revealing temperature differences in the thinned sections. When the temperature inside the pipeline is higher than the pipe’s surface, the thinned areas will show elevated temperatures; conversely, when the internal temperature is lower, the thinned sections will have lower temperatures.

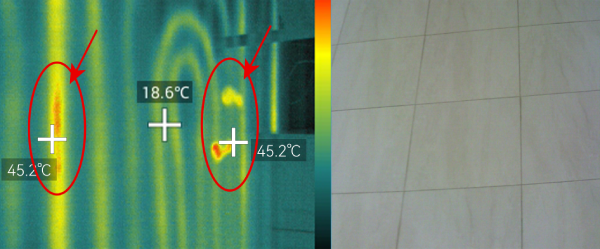

4. Insulation Assessment: Heat and Cold, Vital for Retention

Infrared thermography can also be used to assess the effectiveness of pipeline insulation. This is especially crucial for maintaining the internal heat of the pipeline or preventing freezing. By analyzing the heat distribution across the surface of the pipeline, infrared imaging can quickly identify whether the insulation has been damaged or is missing, and precisely pinpoint the location of any deficiencies.