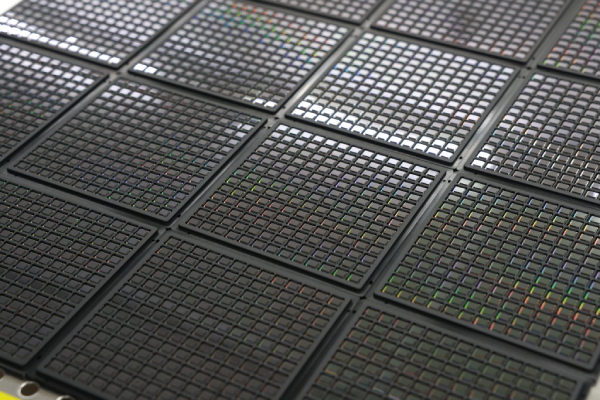

In the modern industrial world, electrical systems are important to operations, and any failure can lead to downtime, costly repairs, or safety risks. To avoid these problems, predictive maintenance strategies have become important, with infrared thermography (IR thermography) being a key tool for detecting electrical failures early. This technology helps find problems before they get worse, improving system reliability and reducing unplanned shutdowns.

What is Infrared Thermography?

Infrared thermography uses thermal cameras to capture the heat given off by electrical parts. Different materials and objects give off different amounts of infrared radiation, and these thermal images show temperature differences that may point to problems. In electrical systems, unusual temperature patterns often mean there are issues like bad connections, overloads, or problems with insulation—things that can cause failure if not fixed in time.

How Does Infrared Thermography Predict Electrical Failures?

Electrical parts naturally make heat while working, but too much heat can signal problems. Infrared thermography helps spot these temperature changes, which are hard to see with the eye. Here’s how infrared thermography can help predict electrical failures:

1. Identifying Overloaded Circuits

When a circuit is overloaded, the wires and connections get hotter than usual. Thermography can find hot spots, helping technicians spot circuits that might fail. Overloaded circuits, if not found early, can cause fires or damage.

2. Spotting Loose Connections

Loose or corroded connections are common causes of electrical problems. These connections create resistance, which leads to extra heat. Infrared thermography can find these hot spots, letting maintenance teams fix the problem before it causes failure or shutdown.

3. Monitoring Switchgear and Breakers

Electrical switchgear and circuit breakers help protect systems from overloads and short circuits. But worn-out parts or internal faults can stop them from working, leading to expensive repairs. Regular infrared thermography checks can find heat patterns in these parts, pointing out problems like broken contacts or failing breakers that could cause system failure.

4. Detecting Faulty Insulation

Good insulation is needed to stop energy loss and keep systems running well. Damaged or old insulation can cause electrical problems, sparks, or fires. Thermal imaging can find areas where insulation is damaged, letting technicians fix the problem before it leads to big issues.

5. Preventing Equipment Overheating

Overheating can happen in many electrical parts, such as transformers, motors, and generators. Thermography can find hot spots on these parts, helping workers notice overheating before it causes component damage, downtime, or fire.

6. Assessing Electrical Panels

Electrical panels hold many parts like breakers, switches, and connectors that must all work well for safety. Thermal imaging helps find unusual heating in these panels, showing possible problems like arc faults, bad connections, or overloaded circuits.

Key Benefits of Infrared Thermography for Electrical Maintenance

1. Early Detection of Potential Failures

The main benefit of infrared thermography is its ability to spot problems before they become serious. Finding issues early can stop unplanned downtime and costly repairs.

2. Non-Destructive Testing

Infrared thermography is a non-invasive method that doesn’t need shutting down the electrical system. This means inspections can be done without stopping operations, making it ideal for regular maintenance.

3. Cost-Effective

Routine infrared checks are cheap compared to the costs of emergency repairs or replacing parts. Finding problems early can save money on downtime, repairs, and replacements.

4. Safety Enhancement

Electrical failures can create dangerous situations, like fires or electric shocks. Thermography helps find hot spots before they become hazards, improving worker safety and lowering the risk of fires.

5. Increased Equipment Lifespan

Regular checks with infrared thermography help extend the life of equipment. Fixing problems early can stop parts from wearing out too soon, reducing the need to replace them.

Implementing Infrared Thermography in Electrical Systems

To get the most from infrared thermography, it’s important to make it part of a regular maintenance plan. Here are some simple ways to use thermography in electrical systems:

1. Regular Scanning

Plan routine thermal scans of electrical parts at least every six months, or more often in high-risk areas. Critical parts should be checked yearly, while older or more used equipment might need checks more often.

2. Trained Technicians

Make sure infrared thermography inspections are done by trained workers who understand the technology and can read the results correctly. Good training helps technicians find both obvious and small temperature changes.

3. Document Findings

Keep a record of all infrared thermography checks, including where the hot spots were found and what actions were taken. This record can help in future inspections and show if preventive actions worked.

4. Combine with Other Predictive Tools

While infrared thermography is great for finding heat problems, using it with other tools like vibration analysis or ultrasonic testing gives a fuller picture of equipment health.