Leak detection is important for keeping industrial systems, buildings, pipelines, and other infrastructure in good condition. Finding leaks early helps prevent expensive damage, improves safety, and ensures everything works properly. Among the many methods for detecting leaks, infrared thermal imaging is one of the most effective and simple technologies.

What is Infrared Thermal Imaging?

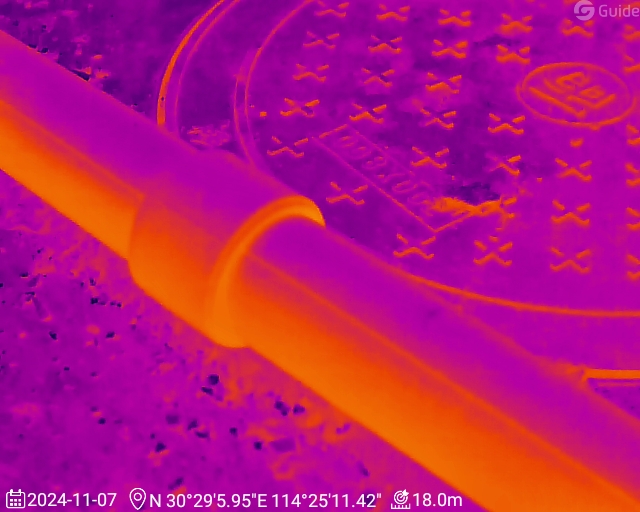

Infrared thermal imaging, also called infrared thermography, is a technology that uses infrared cameras to see temperature changes on surfaces. Every object gives off infrared radiation, which is related to its temperature. Infrared cameras detect this radiation and turn it into images called thermograms. These thermograms show temperature differences that can point to issues, including leaks in pipes, walls, roofs, and even underground systems.

By showing temperature differences on a surface, infrared thermography can find areas where leaks have happened, especially in hard-to-reach places or where other methods might not work.

How Does Infrared Thermal Imaging Work for Leak Detection?

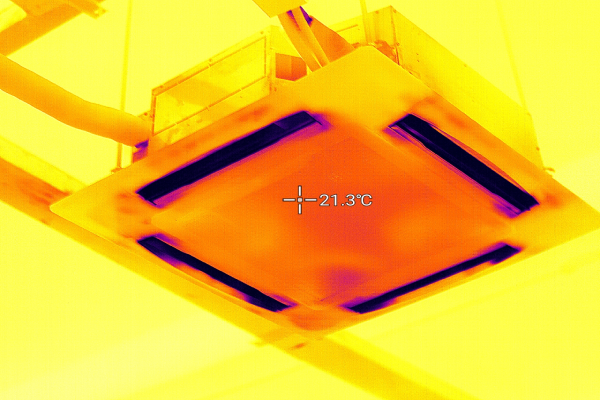

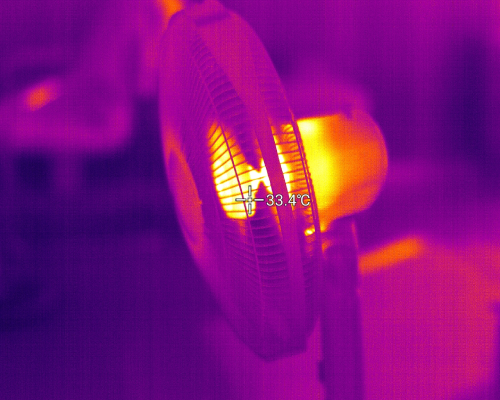

Leaks, whether in plumbing, roofs, HVAC systems, or pipelines, often cause temperature changes in the area around them. When a liquid or gas leaks, it can make the nearby surfaces warmer or cooler. Infrared cameras can detect these temperature changes, and by looking at the thermographic images, technicians can find the leak.

Here is how infrared thermal imaging is used for leak detection:

- Scan the Surface: The technician uses an infrared camera to scan the surface where the leak might be. The camera finds heat differences and shows them on a screen.

- Find Anomalies: Areas with unusual temperatures may show where a leak is. For example, a water leak might make a surface cooler, while a gas leak might make it warmer.

- Analyze Thermograms: Technicians study the thermograms to find the exact location of the leak. This helps them focus on fixing the problem.

- Repair the Leak: After finding the leak, technicians can fix or replace the broken part, reducing damage and repair time.

Key Benefits of Infrared Thermal Imaging for Leak Detection

- Non-Destructive and Non-Invasive: Traditional leak detection methods may need breaking walls, ceilings, or underground pipes. Infrared thermal imaging lets technicians find the leak without causing damage, keeping the structure safe.

- Fast and Efficient: Infrared thermal imaging works quickly and gives results in real-time. Instead of using methods like digging up pipes or tearing open walls, infrared cameras can find the problem right away.

- Preventive Maintenance: By finding leaks early, infrared thermal imaging helps make repairs before bigger problems happen. This saves money and reduces downtime.

- Versatility: Infrared thermal imaging works for many types of leaks—whether in water pipes, gas pipelines, HVAC systems, or roofs and walls.

- Cost-Effective: While infrared cameras might cost more upfront, the long-term savings from reducing damage, repair costs, and downtime make infrared thermography a good choice.

Applications of Infrared Thermal Imaging in Leak Detection

Building Inspections:

- Roof Leaks: Infrared cameras are often used to find leaks in roofs, especially in large buildings. Moisture from leaks causes temperature changes that infrared cameras can easily see.

- HVAC Systems: Leaks in HVAC systems can waste energy and lower performance. Infrared thermal imaging can find air or refrigerant leaks without taking apart equipment.

- Plumbing and Water Leaks: In buildings, leaks in plumbing systems, like water pipes behind walls or floors, can be found by the temperature changes caused by leaking water.

Industrial Applications:

- Oil and Gas Pipelines: Infrared thermography is commonly used to find leaks in oil and gas pipelines, where even small leaks can cause big problems. Infrared cameras detect temperature changes caused by escaping gas or fluids.

- Power Plants: Infrared thermal imaging helps find leaks in cooling systems and steam pipes. Leaks in these systems can be found quickly with infrared cameras.

- Mining and Manufacturing: Infrared cameras can spot leaks in industrial fluid systems, helping prevent machine breakdowns and keeping operations running smoothly.

Underground Leak Detection: Infrared thermal imaging can also find leaks in underground pipes and sewage systems. With advanced infrared cameras, temperature changes caused by leaks can be detected even in buried pipes.

Agriculture: In agriculture, thermal imaging helps find leaks in irrigation systems, making sure water is distributed well and crops are not over- or under-watered.